- Top

- For Corporations

- Kitakyushu New Low-Carbon Measurement, Reporting and Verification Mechanism (K-MRV)

Kitakyushu City Project for Establishing a New Mechanism for Low Carbon Emission (K-MRV)

Branding support for environmental technologies

Kitakyushu New Low-Carbon Measurement,Reporting and Verification Mechanism(K-MRV)Project Outline

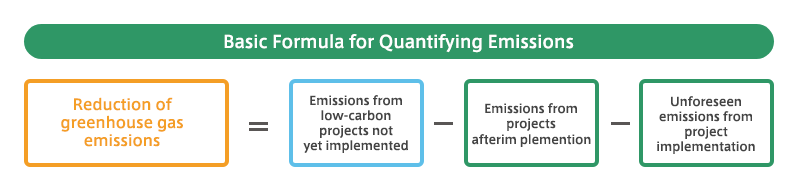

The Kitakyushu New Low-Carbon Measurement, Reporting and Verification Mechanism (K-MRV) visibly quantifies greenhouse gas reductions through low-carbon projects carried out in Asia by the City of Kitakyushu and local businesses in Kitakyushu. By visually quantifying greenhouse gas emissions, the mechanism will promote the export of high, value-added technologies of local businesses and stimulate the local economy, in order to contribute to the reduction of greenhouse gas emissions in the entire Asian region. The mechanism is also designed for coordination with Japan’s Joint Crediting Mechanism (JCM).

MRV is the acronym for the “measurement,” “reporting,” and “verification” of greenhouse gas emission reductions, and is made up of the first letter of each word. The K-MRV is Kitakyushu’s version of the MRV

Target Projects

In principle, target projects are those that contribute to the following three types of low-carbon activities carried out in overseas.

- Projects implemented or being implemented with the City of Kitakyushu as the main implementation body

- Projects implemented or being implemented by businesses with offices in Kitakyushu

- Projects implemented or being implemented by businesses outside Kitakyushu that are supported by the City of Kitakyushu

Submit Your Application!

Applications can be submitted at any time. Individual methodologies and projects will be approved after applications are reviewed by the Kitakyushu New Low-Carbon Mechanism (K-MRV) Committee, which is a panel made up of external experts.

Advantages

- Approved projects will receive a K-MRV certificate and are permitted to use the K-MRV logo mark.

※Can be used as PR for technologies and projects - The Kitakyushu Asia Center for Carbon Neutrality supports the implementation of overseas projects (acquisition of menu of support from the national government, added assessment points in applications for city-sponsored subsidies to small- and mid-sized companies as support for the development of environmental businesses in Asia, etc.).

Application Flow Chart

Approved Projects & Individual Methodologies

A list of projects and individual methodologies that have been approved to date can be found below

| No.1 | |

|---|---|

| Project Proponent | Yaskawa Electric Corporation |

| Title | Introduction of inverters into factories in China |

| Description | Project to reduce the amount of energy used by introducing inverters into iron and steel factories in China |

| Estimate Emission Reduction(tCO2/y) | 68,698 |

| No.2 | |

| Project Proponent | Hohkohsya Co., Ltd. |

| Title | Renewed introduction of energy-efficient CCFL lighting in the Kingdom of Thailand |

| Description | Project to reduce the amount of electricity used by converting existing fluorescent lighting (555 tubes) to energy-efficient CCFL lighting (cold cathode fluorescent lamps) in a factory of Katata Electric (Thailand) Co., Ltd. in Rayong Province in the Kingdom of Thailand |

| Estimate Emission Reduction(tCO2/y) | 23 ※555 tubes in onefactory only |

| No.3 | |

| Project Proponent | TOTO Ltd. |

| Title | Introduction of water-saving showers and toilets in one hotel in Viet Nam |

| Description | Project to reduce the amount of water used in hotels by introducing water-saving showers and toilets in 150 rooms in one hotel in Viet Nam |

| Estimate Emission Reduction(tCO2/y) | 5 ※Demonstration project in FY 2013 150 rooms only |

| No.4 | |

| Project Proponent | City of Kitakyushu, Japan |

| Title | Introduction of the Takakura composting method in households in Surabaya, Indonesia |

| Description | Project to reduce the amount of greenhouse gas emissions through composting in the City of Surabaya, Indonesia. The City of Kitakyushu has distributed composting kits to 17,033 households in Surabaya as part of the first international cooperation project for the Takakura composting method that has been expanded to 80,000 households. |

| Estimate Emission Reduction(tCO2/y) | 1,390 |

| K-MRV001 | |

|---|---|

| Title | Improvement of the efficiency of equipment, such as fan pumps, through the introduction of inverters |

| Description | Methodology to introduce inverter technology to be used as motors and controllers for drives that serve as a source of energy for the power equipment of infrastructure owned by factories (fans, pumps, compressors, and the complex systems formed by this equipment). |

| K-MRV002 | |

| Title | Reduction of water consumption through the introduction of water-saving showers |

| Description | Methodology to introduce shower equipment technology to control the amount of hot water used while guaranteeing a comfortable bathing environment. |

| K-MRV003 | |

| Title | Reduction of water consumption through the introduction of water-saving toilets |

| Description | Methodology to introduce toilet equipment technology with the same or better flushing capacity as conventional toilets, and requiring a lower amount of water for flushing. |

| K-MRV004 | |

| Title | Prevention of methane emissions through household composting of organic waste |

| Description | Methodology to introduce the composting technology used by the Takakura composting method to compost organic waste easily and cost-effectively. This is achieved through natural decomposition by mixing cultured microorganisms that can be acquired locally with organic waste. |

| K-MRV005 | |

| Title | Reduction of energy consumption through the introduction of high-efficiency lighting |

| Description | Methodology to introduce CCFL technology that has the following advantages: same level of energy-saving performance and lifespan as LED lighting, limited heat generation, and good color rendering performance. |

| K-MRV006 | |

| Title | Combined heat and power through co-generation |

| Description | Methodology to introduce technology that aims to reduce the amount of fossil fuels consumed. This is achieved by grouping individual users, and converting conventional heat utilization by boilers and power supply produced by power systems or private power generation to the production of combined heat and power (CHP) through co-generation systems. |

| K-MRV007 | |

| Title | Reduction of CO2 emissions by expanding the use of low-carbon concrete that uses artificial pozzolan containing metakaolin. |

| Description | Methodology to introduce technology that aims to improve the performance of concrete and reduce GHG emissions. This is achieved by replacing a part of cement that is used as raw materials in the manufacturing of concrete with an admixture that uses industrial by-products (artificial pozzolan that contains metakaolin). |